How to install MotoMat Tiles

Installation and Advisory Notes

These notes refer to

MotoMat Recycled 470 x 470 x 14mm Tiles

Mototile MotoMat Anti fatigue interlocking tiles are designed to lower the risk of standing in the workplace or where you are stationed for long periods of time and are suitable for indoor or outdoor use. All tiles can be laid generally over any hard, clean and level surface. To get the best results for your new floor and to ensure a trouble free and long working life from the tiles we offer the following guidelines and advice. Many of the issues we mention are common to all PVC based tiles or floor paints but we have tried to minimize them in our designs.

Witness Marks and Surface finish

As with all PVC Tiles the method of manufacture may Result in a witness mark being visible in the tile at the central injection moulding point and also along the flow lines from the centre and around the external edges of the tile, this mark is unavoidable.

Please check the tiles before you commence laying, if the marking is unacceptable to you do not continue with installation. As we will not accept responsibility to replace or refund the cost of any goods after 5m2 or more.

Exposure to sunlight

Exposure to direct sunlight may lead to certain sections of the tiles heating up and expanding unevenly compared to the rest of the floor, resulting in the edges of the tiles curling up or causing distortion in neighboring tiles. For spaces featuring roller doors, expansive windows, skylights, or south-facing bays, it is highly advisable to securely adhere the tiles to prevent them from losing their intended shape.

Colour match, traceability and batch control

Each order is supplied fully from a single batch and we cannot guarantee perfect colour consistency, to a level of 100%, between batches. Should you wish to purchase additional tiles at a later date we cannot guarantee subsequent orders will be supplied from the same batch.

The batch number is clearly shown on your paperwork, which you should retain for reference.

Chemical Resistance

While PVC demonstrates strong resistance against a wide range of chemicals, itís important to exercise caution, particularly with solvent-based chemicals, especially if employed as degreasers or thinners. Petrochemicals such as petrol and diesel may harm the elastomer within the tiles if left unattended for prolonged durations. Prompt cleanup is advised for fuel spillages to prevent potential damage.

Basic Installation & Advisory Notes requirements for all ranges

Sweep and / or vacuum through the floor so you can inspect it Fill any substantial holes or cracks in the floor and remove any protruding lumps and bumps If the floor is a tampered effect we would advise you to screed the floor to get the best level finish.

E.g. With a rapid cure self-levelling compound. The flatter and smoother the floor the better the end finish will be.

We typically discourage installing tiles over carpet, if unavoidable, we recommend employing a polyethylene film between the substrate and the tiles. All PVC based tiles expand and contract as temperatures change. At very low temperatures the tiles become harder, less flexible and subject to contraction while, at high temperatures, the tiles become softer, more flexible and subject to expansion. With this in mind we offer the following advice.

The minimum recommended temperature for installing the tiles is ± 15°C. Also, please be aware that ovens and catalytic converters emit heat which can cause expansion in the flooring.

You must always leave the tiles to acclimatise before laying them. Open up all the boxes, spread the tiles evenly still in the boxes over the area you will be laying and leave for a minimum of 24 hours before commencing fitting. This process also enables you to check tile quality & quantities before you begin fitting.

When fitting allow a minimum 5mm expansion gap between the floor and fixed points like walls, piers or around very heavy objects (e.g. racking, work benches etc.) to allow for any slight expansion or contraction due to temperature changes.

Do not try to install directly after you have received your delivery - be patient!

Tiles can be laid without using adhesives for most applications although there are some circumstances, noted below, where gluing certain tile areas to the floor is advised.

For example

You may need to glue down tiles or ramps that are exposed to prolonged direct sunlight, which may cause tiles to become displaced as they soften and expand more quickly than the rest of the floor area, such as shop fronts, south facing, glass doors etc.

If the tiles will continue through a doorway into an adjacent area we recommend that these tiles be glued down.

If you need to use full or nearly full steering lock when driving into the garage then tiles may be twisted out of their interlock and have to be refitted. We recommend that you glue down tiles that could experience strong turning forces.

Tools required

All you will need to lay the tiles in most cases are: A white non-marking rubber mallet, which we can supply a hand saw, a standard woodworking panel saw or a power jigsaw for cutting.

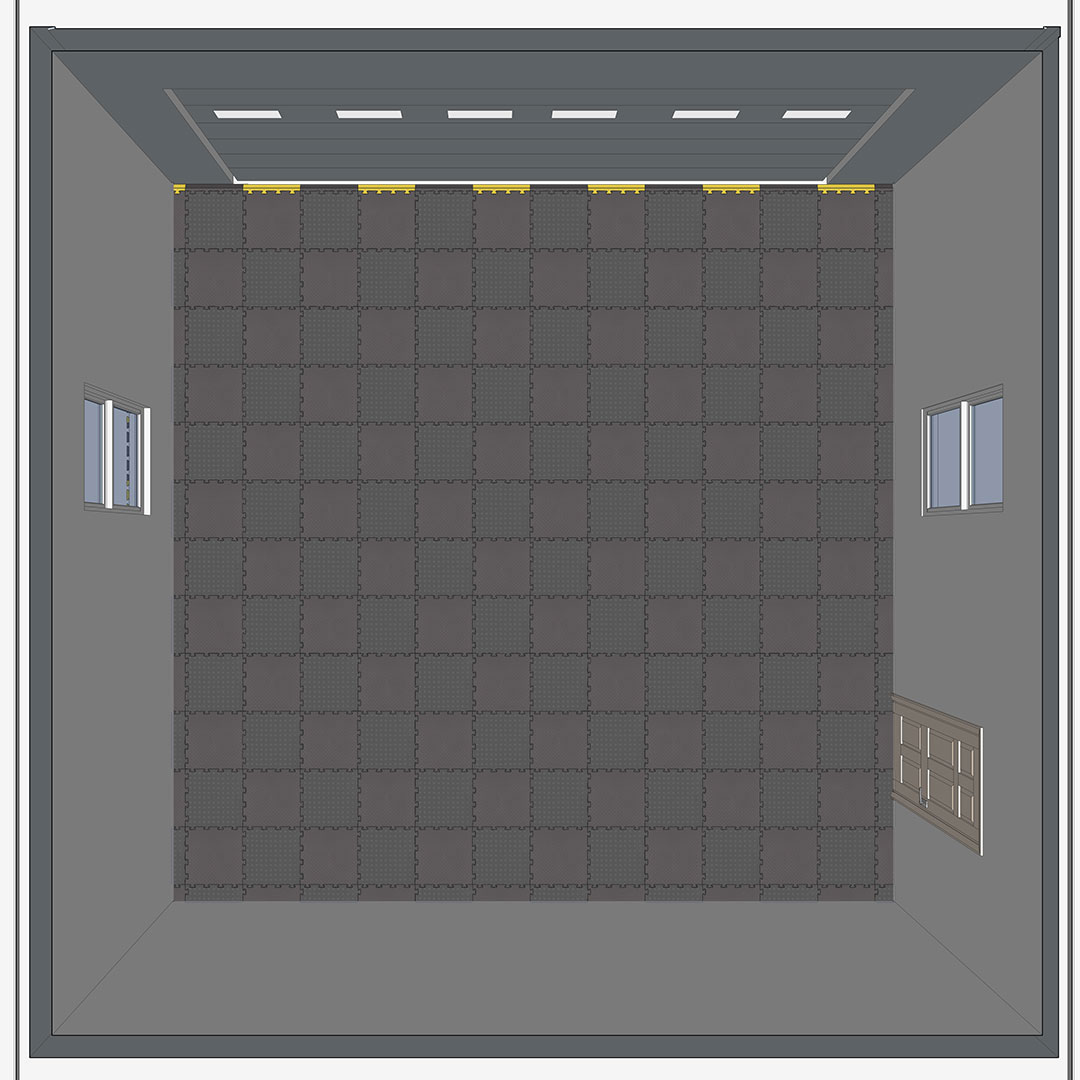

Floor Installation Tips MotoMat - Recycled/Virgin Material

There is no hard and fast rule whether you install the ramps first or last. The advantage of installing the ramps at the end but before doing final cuts is that it then allows you to physically move the complete mat (2 people generally required) to align in case the walls are not square, please ensure that if you do need to move the mat that you keep the equal gap on the left and right hand side.

NOTE: This guide assumes you are fitting tile ramps in the garage entrance. It is strongly recommended that you do fit tile ramps to protect the edges of the garage flooring, to stop movement of the tile 'mat' and to prevent a trip hazard.

From test installations we have found that the method suggested below usually has the quickest floor laying time combined with the most satisfying finish, especially where patterned garage flooring is being laid. One alternative we have used is to fit the tile ramps first and then install the tiles row by row left to right later.

Tools you will need:

Tape measure, a standard woodworking panel saw, board to cut tiles on. A non-marking rubber mallet and a steel or similar straight edge may be useful.

Please ensure that the triangle corner is always in the same position for each and every tile.

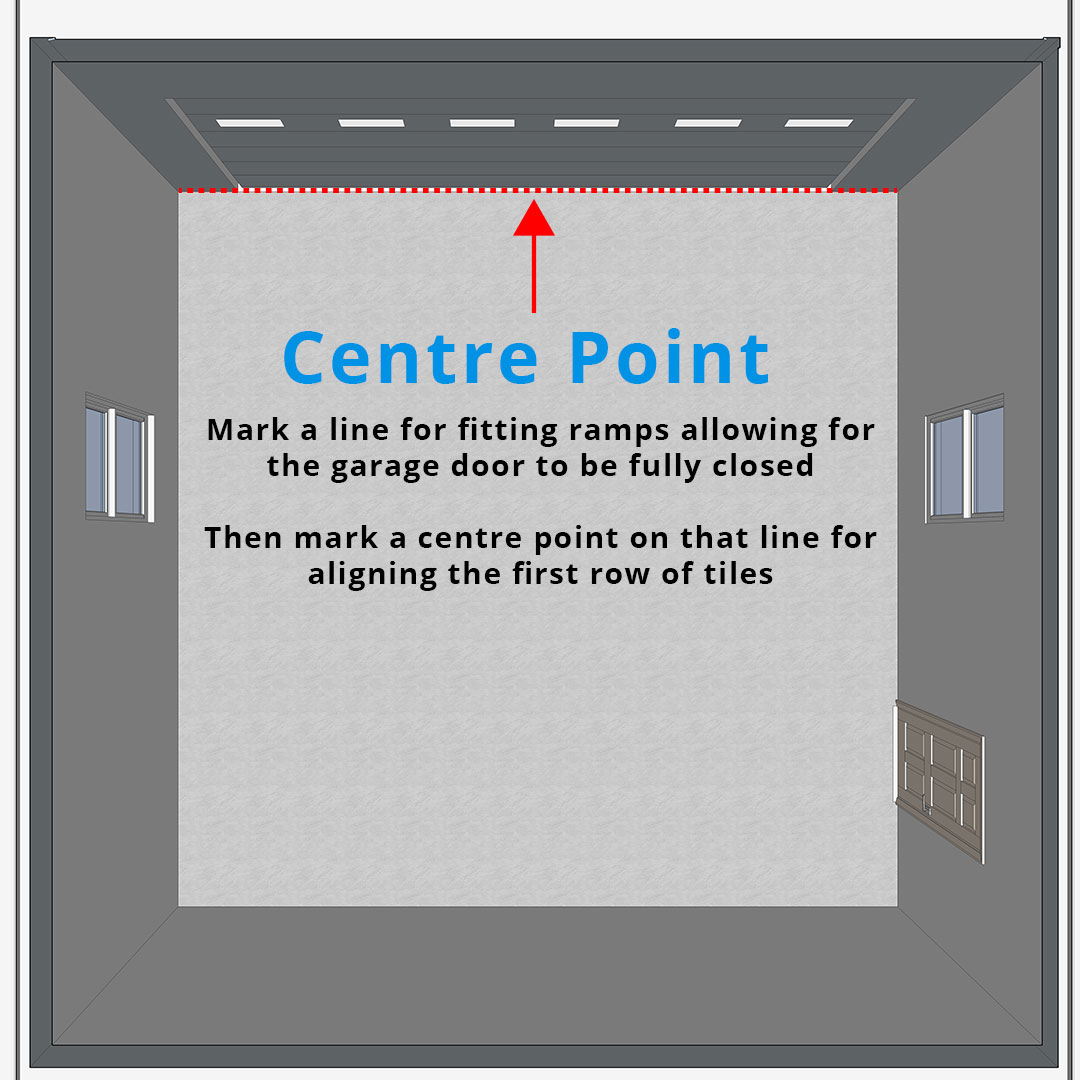

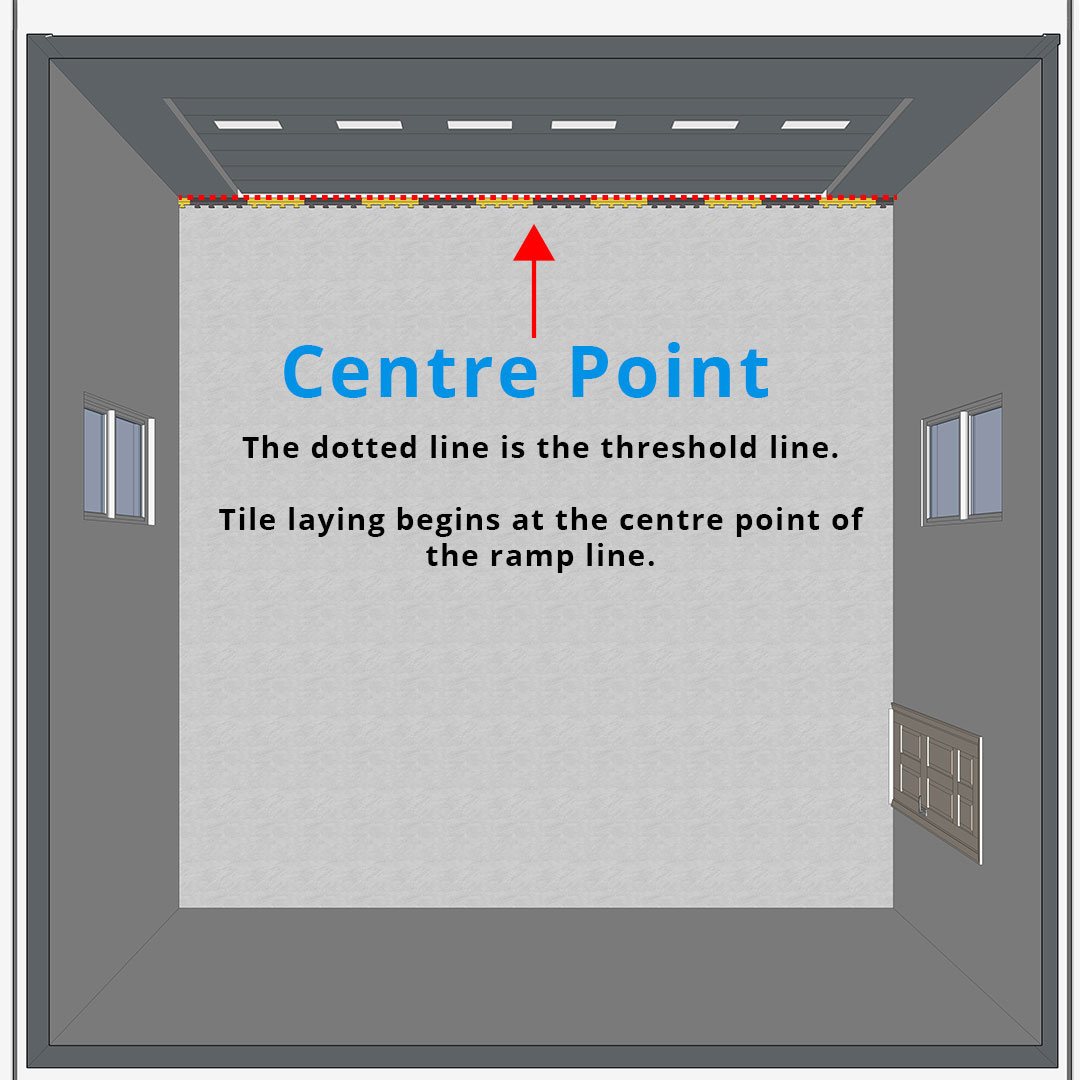

Stage 1 - Start at the door and draw a threshold line:

From inside the garage, with the door(s) closed, establish the line which the front of the tile ramps must not cross so that the door can be closed properly once the ramps are installed.

We will call this line the threshold line. Mark this line clearly for later use and re-open the door(s).

Stage 2 - Draw a tile ramp line and mark the centre

Align the front edge of a length of ramp carefully with the threshold line and determine a new line where the tiles and ramp will lock together in the finished installation. We will call this the tile ramp line.

Run a tape measure along the tile ramp line and mark the centre point.

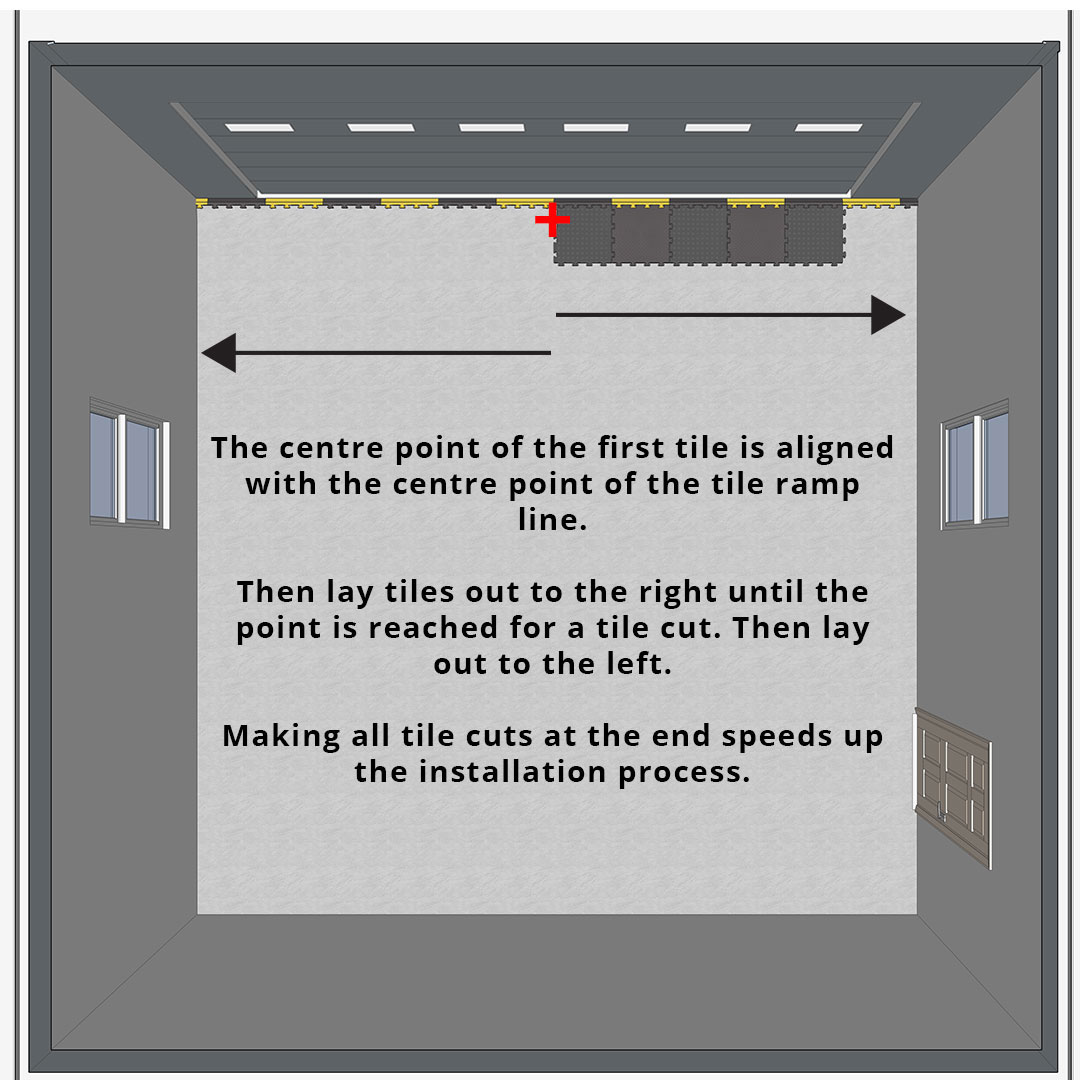

Stage 3 - Start laying tiles

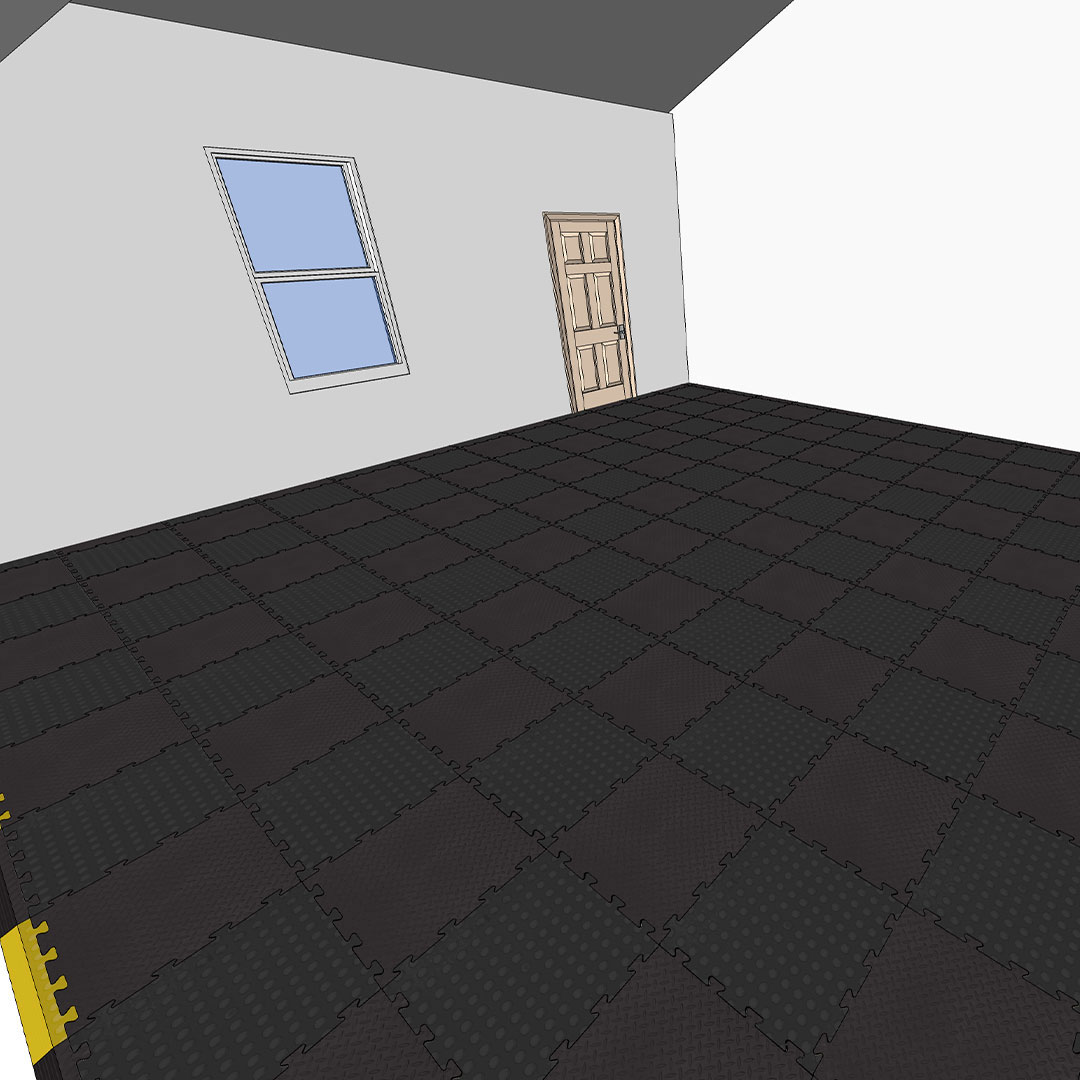

Lay your first tile so that the front edge of the tile sits where you propose to have the back of the ramp. Align your first tile's centre to the tile ramp line's centre point.

Then work out from this tile to the side (eg the right) laying across one tile at a time until you reach the point where you have a gap smaller than a whole tile before meeting the garage wall.

Leave this gap and all subsequent ones. Making all tile cuts at the very end speeds up and simplifies laying the flooring.

Please do not force the tiles together, offer up the corner of the tiles and using the non-marking rubber mallet tap the joints together gently. If tiles are not locking together without a lot of force then they may not be properly aligned or you are doing something wrong.

Now lay tiles out to the opposite wall of the garage, repeating the process above.

You should leave an equal gap on the left hand side and the right hand side before the wall.

Once the first row is complete then commence laying the next row back in the same manner.

Repeat this until all uncut tiles are laid and you have a small gap from the back row of tiles to the wall.

Stage 4 - Straighten the tile mat and align to ramp

You now have the opportunity to straighten the whole mat you have assembled and realign if required.

Now fix ramp to the required position at the front of the garage (a good quality construction adhesive is recommended for final fixing of ramps) - if required pull the tile mat forwards so that the front row of tiles sits onto the ramp.

We now suggest that you leave the floor to settle for 24 hours before commencing final cutting and fitting of tiles around your perimeter. Generally the tiles that you cut to size from the left of the garage, the offcut can be used on the right hand side of the garage.

Stage 5 - Perimeter tile cuts

You may now commence laying the cut tiles around the walls' perimeter. We used a standard woodworking panel saw and jigsaw for all our cuts in a test installation.

When measuring the tiles to cut we would suggest that you use three measuring points on each tile.

If cutting the tiles with a standard woodworking panel saw make sure it has a sharp blade. It is better to make several light scoring cuts rather than one heavy cut.

Start at the front of the garage again. Measure and cut the first row tile on the right. Allow for a 5mm expansion gap between tiles and wall. The repeat this process on the left hand side tile on the first row.

Repeat the process above for the next row back and continue until you get to the final row against the back wall of the garage.

Experience has taught us to lay the tiles in the left and right back corners last (ie. the tiles farthest from the first tile laid).

Measure, cut and fit all the other tiles on the back row then carefully measure, cut and fit the last two corner tiles.

After Care Advice: Cleaning, Maintenance and General Use

Regular light cleaning once a week is better than a heavy clean once a month. Brush or vacuum the floor first then sponge mop using a normal household, non-abrasive, floor cleaning detergent (neutral ph.) at a weak concentration. Use a damp mop rather than soaking the floor with a lot of water.

Catalytic converters and exhaust systems can get extremely hot so we recommend that you do not leave your vehicle parked and running on your Mototile floor as tiles could overheat and become displaced or damaged. Vehicles with a low ground clearance should be allowed to cool off before driving onto the tile floor to avoid deformation or damage to tiles.

Tyre marks and stamps

Tyres may, sooner or later, mark or stain the tile due to a chemical reaction between additives in the tyre compound and the plasticizer used in the production of the tile. This staining reaction can occur with most floor coverings including tiles, vinyl and paints.

To reduce the risk of tyre marking consider using Black or Graphite Grey tiles in the areas where your wheels will sit. Should staining occur it would be less obvious or visible on darker coloured tiles.

We cannot predict if or when a tyre compound reaction may occur and do not consider tyre staining to be a defect in the product, so we are unable to replace tyre stained tiles free of charge. We have tested acetone for removing tyre stains and found it to be very effective.

If you feel that your floor is likely to have staining regularly from tyres, chemicals or hair dyes etc. we have had some success and recommend the Floor Cleaner R1000 by Dr. Schutz. It cleans, protects and adds safety to your flooring in one step. Enhances the anti-slip properties, creating a water-soluble protective film. For more information and purchase options of this Floor Cleaner R1000 product click or go to: https://drschutz.co.uk/retail/floor-cleaner-r1000/ Please contact us for more information or help.

Pressure Points - Car Jacks and Bike Stands

PVC based tiles will compress under heavy loads concentrated on a small area, such as car jacks, bike stands, fork lift trucks etc. but will always return to their original shape. However, we advise exercising caution or conducting additional assessment for the following truck types: 3-wheel electric trucks with a single rear drive wheel (especially those with nylon wheels), Reach trucks and aisle stackers with small, hard wheels, and Trucks bearing extremely heavy loads with small wheels. These vehicles are known to cause damage to various types of flooring, including epoxy and concrete. To prevent any potential issues with the MotoMat tiles, itís recommended to secure the floor with adhesive in areas frequented by such vehicles or to use a suitable board beneath jacks and stands to spread the weight evenly over a wider area.

The MotoLock Heavy Duty tile is the only tile that we recommended for use in Industrial applications.

Just click the button below to download and print out this MotoLock installation guideline.